Lean Management Training Program Overview in Lancaster, OH

You're already identifying waste, spotting inefficiencies, and proposing process improvements - but without formal recognition, your ideas often get overlooked. Lean-certified professionals lead enterprise transformation programs, report directly to operations VPs, and command premium compensation for applying systematic waste elimination strategies that you've already been attempting. Promotions to Operations Manager or Continuous Improvement Lead increasingly require a Lean Management certification, and this is where your career trajectory changes. Our Lean Management Training Program isn't a theoretical course. It's designed by practitioners who've led real transformations at Tata, Mahindra, Bosch, and other manufacturing operations in Lancaster, OH. These environments involve legacy systems, union constraints, and budget limitations - situations textbooks rarely cover. This Lean management course equips you to implement Lean systems in organizations resistant to change, providing a structured approach that turns operational ideas into measurable results. Unlike programs that teach Lean tools in isolation - like 5S workshops or Kanban boards - our Lean Management certification online program develops operational leaders capable of driving sustainable transformation. You'll master value stream mapping to uncover hidden waste costing lakhs monthly, design pull systems that reduce inventory without causing stockouts, and lead kaizen events that deliver documented, actionable savings rather than temporary improvements. The Lean Management certification validates your skills, but the real advantage is presenting a transformation roadmap with projected ROI that earns immediate executive buy-in. This Lean management course is designed for working professionals in manufacturing, healthcare, IT operations, and service sectors who cannot stop production to study. We offer flexible weekday evening and weekend batches, fully interactive sessions, and real gemba walks at operational facilities. Every session is recorded for later review. Beyond training, you gain ready-to-use value stream mapping templates, A3 problem-solving frameworks adapted from Toyota operations, 24/7 expert support, and hands-on coaching for your mandatory capstone improvement project. This ensures your Lean Manager skills translate directly into impactful, measurable results.

Lean Management Course Highlights

Globally-Recognized Certification Body Alignment

Train through a program that aligns with internationally accepted Lean certification standards, ensuring your credential translates across industries and geographies.

Practitioner-Led Instruction by Lean Experts

Learn from certified Lean practitioners who've led transformations at scale and can teach you the political and technical realities of change management in complex organizations.

Flexible Training Schedules for Working Professionals

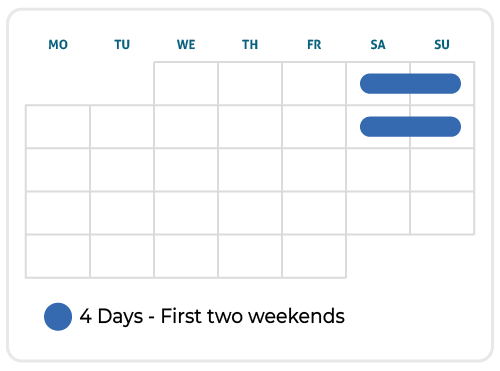

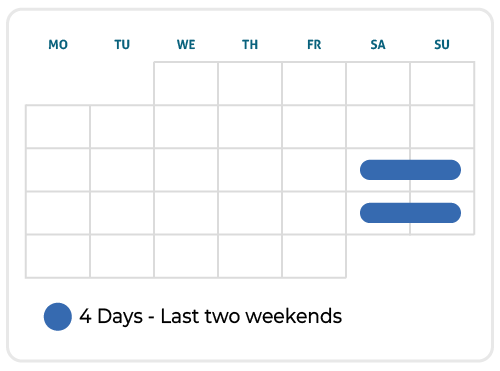

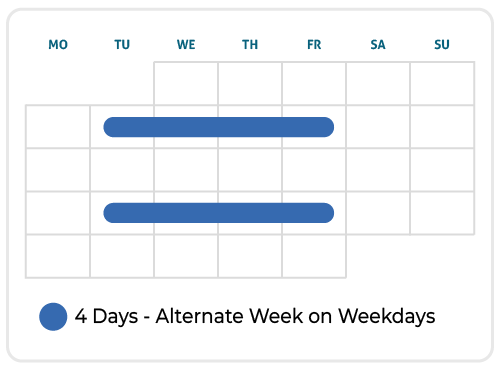

Access weekend-only batches, weekday evening sessions, or intensive 10-day bootcamps that don't require career breaks or extended leave from work.

Hands-On Gemba Learning Experience

Participate in actual shop floor walks, value stream mapping exercises, and process observations at manufacturing and service facilities in Lancaster, OH.

Comprehensive Lean Toolkit Development

Master the full spectrum of Lean tools?VSM, 5S, SMED, Kanban, TPM, Poka-Yoke, Standard Work?with templates and implementation guides for immediate workplace application.

24/7 Project Implementation Support

Access our team of Lean coaches around the clock for guidance on your improvement projects, stakeholder challenges, and measurement system design.

Corporate Training

Ready to transform your team?

Get a custom quote for your organization's training needs.

Upcoming Schedule

Skills You Will Gain In Our Lean Management Program

Value Stream Thinking

Stop optimizing individual departments while the overall flow suffers. You'll learn to map end-to-end value streams, identify where value is actually created versus where waste accumulates, and design future-state processes that eliminate non-value-added activities systematically.

Waste Identification & Elimination

Recognize the seven (or eight) forms of waste hiding in plain sight within your operations. You'll develop the diagnostic capability to quantify waste's impact on cycle time, cost, and quality, then systematically eliminate it using targeted Lean tools appropriate for each waste type.

Flow & Pull System Design

Understand why batch-and-queue systems create inventory, delays, and quality problems. You'll master the principles of one-piece flow, takt time calculation, and pull system design using Kanban that synchronizes production with customer demand and eliminates overproduction waste.

Standard Work & Visual Management

Stop relying on tribal knowledge and undocumented best practices that disappear when key people leave. You'll learn to develop standard work that captures current best methods, establish visual controls that make abnormalities instantly visible, and create management systems that sustain improvements.

Problem-Solving & A3 Thinking

Move beyond symptom treatment to root cause elimination using structured problem-solving. You'll master A3 methodology that documents current conditions, identifies root causes through data analysis, develops countermeasures, and establishes follow-up mechanisms that prevent problem recurrence.

Change Leadership & Lean Culture

Recognize that tools without cultural change create temporary improvements that fade. You'll develop frameworks for managing resistance, building problem-solving capability at all organizational levels, and establishing leader standard work that reinforces Lean behaviors daily.

Who This Program Is For

Operations Managers

Plant Managers & Production Supervisors

Continuous Improvement Managers

Supply Chain Managers

Quality Managers

Industrial Engineers

If you lead projects and meet PMI's mandatory experience requirements, this program is engineered to get you certified.

Lean Management Training Program Roadmap

Why Get Lean Management Certified?

Unlock Career Growth in Operational Excellence

Stop being overlooked for operations leadership roles because you lack the formal credential that validates your improvement capability to skeptical executives and HR gatekeepers.

Earn Organizational Credibility and Influence

Command operational respect across departments as leaders recognize that you possess the systematic methodology to drive sustainable change, not just temporary improvements.

Shift from Firefighting to Strategic Process Design

Transition from reactive problem-solving to proactive system creation by mastering tools that prevent issues before they arise, ensuring consistency, efficiency, and long-term success.

Eligibility & Prerequisites

Lean Management certification is designed for working professionals who lead or influence operations and are ready to drive systematic improvement. Unlike entry-level awareness courses, this program requires demonstrated capability to lead improvement projects and deliver measurable results. Here's what you need to qualify for certification.

Operational Leadership Experience: Most certification bodies require 2-3 years of experience in operations, production, or process improvement roles where you've led teams or influenced operational decisions.

Completion of Lean Training: You must complete formal Lean training covering all core principles and tools; this program fully satisfies that requirement with comprehensive coverage of the Lean Body of Knowledge.

Led & Completed Improvement Project: You must successfully lead at least one significant improvement initiative using Lean methodology, demonstrating measurable operational impact and proper application of tools.

Documented Operational Impact: Your project must deliver quantified improvements in key metrics like cycle time reduction (minimum 20-30%), productivity improvement, quality enhancement, or cost savings with validated before/after data.

Additional Requirements: For comprehensive details on project documentation requirements, measurement system design, and certification body-specific criteria, refer to our detailed FAQ section.

Course Modules & Curriculum

Lesson 1: Takt Time, Cycle Time & Flow Principles

Understand the mathematics of flow and how to synchronize production with customer demand. Learn to calculate takt time from customer requirements, assess whether processes can meet takt, identify bottlenecks that constrain flow, and balance work content across operations. Master the principles of continuous flow, one-piece flow benefits and challenges, and when batch-and-queue is appropriate versus flow.

Lesson 2: Kanban Systems & Pull Production

Shift from push to pull production with Lean Management practices. You'll learn to design Kanban systems for raw materials, WIP, and finished goods to prevent overproduction and reduce inventory costs. Master Kanban card calculations, supermarket layout design, replenishment logic, and the behavioral changes required to implement pull thinking effectively. These skills are essential for any aspiring Lean Manager and are core components of our Lean Management course.

Lesson 3: Quick Changeover & SMED Methodology

Eliminate the batch size penalty by reducing changeover times from hours to minutes. Learn Shigeo Shingo's Single-Minute Exchange of Die methodology: separating internal from external setup activities, converting internal to external, streamlining remaining internal activities, and eliminating adjustment. Understand how quick changeover enables smaller batches, reduces inventory, and improves responsiveness to customer demand variation.

Lesson 1: Jidoka & Built-In Quality Systems

Build quality into processes rather than inspecting defects out later. Learn the principle of Jidoka (automation with human intelligence), how to design processes that stop when abnormalities occur, and methods for separating people from machines to improve utilization. Master andon systems for visual signaling, escalation procedures that bring help to problems immediately, and root cause problem-solving that prevents recurrence.

Lesson 2: Poka-Yoke & Error-Proofing Methods

Design processes that make it impossible to create defects even when people make mistakes. Learn the hierarchy of mistake-proofing from elimination and replacement through facilitation and detection. Master poka-yoke principles for manufacturing and transactional processes, understand the difference between control and warning devices, and develop creativity in designing low-cost error-proofing solutions.

Lesson 3: Standard Work for Quality & Consistency

Document and continuously improve the current best method for every process. Learn to develop standard work that specifies takt time, work sequence, and standard work-in-process. Master standard work documentation methods, visual job instruction training, and the discipline of adherence measurement. Understand that standards are the baseline for improvement, not rigid constraints on innovation.

Lesson 1: 5S System Implementation & Sustainability

Create organized, visual workplaces where abnormalities are immediately apparent. Learn to implement 5S (Sort, Set in Order, Shine, Standardize, Sustain) in manufacturing and office environments. Master red-tagging methodology for Sort, ergonomic principles for Set in Order, cleaning-as-inspection for Shine, visual standards for Standardize, and audit systems for Sustain. Understand why 5S is the foundation for flow and quality, not just housekeeping.

Lesson 2: Visual Controls & Management Systems

Make process status, performance, and problems visible to everyone without asking questions. Learn to design visual boards that communicate production status, quality performance, safety metrics, and improvement activities. Master tier meeting structures (from cell huddles to plant reviews) that cascade information and escalate problems systematically. Develop visual workplace principles that enable management by exception rather than constant supervision.

Lesson 3: Total Productive Maintenance Foundations

Reduce equipment breakdowns and prevent capacity losses that disrupt flow and create waste. Learn the eight pillars of Total Productive Maintenance (TPM), emphasizing autonomous maintenance and planned maintenance systems. Master Overall Equipment Effectiveness (OEE) calculations to measure availability, performance, and quality losses. Applying these Lean Management practices allows a Lean Manager to shift maintenance from reactive firefighting to proactive prevention, a crucial skill for any professional completing a Lean Management course or pursuing Lean management certification.

Lesson 1: A3 Problem-Solving Methodology

Master Toyota's systematic approach to root cause problem-solving and knowledge capture. Learn A3 structure: background and current condition, goal and gap analysis, root cause analysis using tools like 5-Why and fishbone diagrams, countermeasure development, implementation planning, and follow-up mechanisms. Develop the discipline to document thinking on one page, making problem-solving transparent and improvable.

Lesson 2: Kaizen Events & Rapid Improvement

Lead focused improvement workshops that deliver results in days rather than months. Learn to select appropriate kaizen targets, assemble cross-functional teams, facilitate structured problem-solving workshops, implement changes rapidly using PDCA cycles, and document before/after results. Understand when kaizen events are appropriate versus when systemic transformation requires deeper intervention.

Lesson 3: Leader Standard Work & Coaching Kata

Sustain Lean improvements through disciplined leadership behaviors and systematic capability development. Learn to develop leader standard work that ensures leaders spend time where value is created, coach problem-solving rather than solving problems for people, and reinforce Lean behaviors through daily actions. Master coaching kata methodology for developing scientific thinking capability throughout the organization, creating a culture where problem-solving is everyone's job.