Lean Six Sigma Yellow Belt Training Program Wheaton, IL

Your Lean Six Sigma Yellow Belt certification isn't just a certificate - it's how you get noticed by management. Working in operations, quality, or manufacturing without formal process improvement training can leave you stuck doing routine tasks while colleagues talk about DMAIC, control charts, and process capability. Meanwhile, professionals with Lean Six Sigma Yellow Belt certification online or in-person actively contribute to improvement projects, join cross-functional teams, and build resumes that qualify them for Green Belt training and higher-value roles. This Lean Six Sigma Yellow Belt course is designed by practicing Black Belts and Master Black Belts who lead improvement programs. Yellow Belts aren't passive observers - they are active contributors who need practical capability, not just awareness. Our program equips you to immediately participate in projects, collect data correctly, and understand the methodology driving your organization. Unlike introductory courses that provide superficial exposure, we build capable team members who can contribute meaningfully. You'll learn how to identify the eight wastes in your processes, use basic statistical tools to analyze data, participate effectively in kaizen events, and support Green Belts and Black Belts with data collection and process documentation. The certification validates your foundation - the real value is becoming the team member who understands improvement methodology and gets selected for high-visibility projects instead of being stuck in business-as-usual operations. We've built this for working professionals in manufacturing, services, healthcare, and IT who need foundational capability fast. Intensive 2-day bootcamp or flexible weekend format, fully interactive with real case studies from Wheaton, IL organizations. Every session recorded. Beyond the training, you get Lean and Six Sigma quick reference guides you can use on projects immediately, basic statistical templates, 24/7 expert support, and clear guidance on qualifying for Green Belt certification - the natural next step that most Yellow Belt programs mention but provide no roadmap for achieving.

LSSYB Training Course Highlights Wheaton, IL

Industry-Recognized Curriculum

Training aligned with the globally accepted Lean Six Sigma Yellow Belt Body of Knowledge.

Taught by Six Sigma Practitioners

Instructors are experienced Black Belts and Master Black Belts with real project expertise.

Flexible Schedule Options

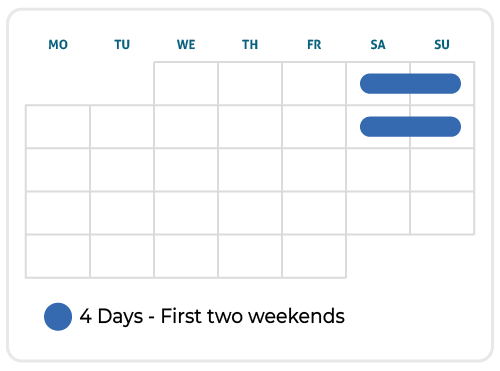

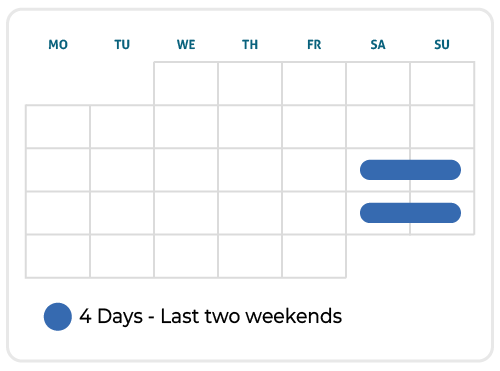

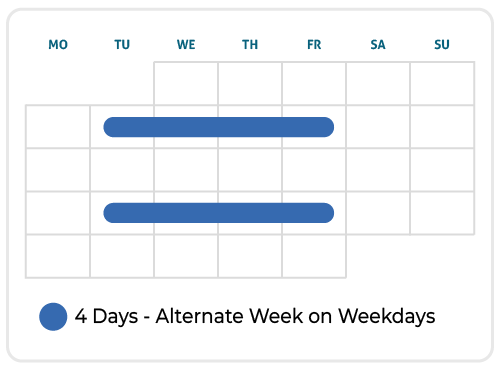

Choose weekday evening, weekend, or intensive bootcamp formats suitable for working professionals.

Hands-On Project Work

Learn through real case studies and project simulations replicating real workplace improvement scenarios.

Comprehensive Practice Materials

Access 500+ practice questions, mock tests, and a project implementation toolkit.

Lifetime Expert Support

Get ongoing guidance and clarification from Six Sigma experts whenever needed.

Corporate Training

Ready to transform your team?

Get a custom quote for your organization's training needs.

Upcoming Schedule

Skills You Will Gain In Our LSSYB Training Program - city83647

Waste Identification

Stop accepting inefficiency as "normal". You will learn to identify the 8 wastes (DOWNTIME) in any process and quantify their impact on cost, quality, and delivery time.

Data Collection & Measurement

Cut through opinions and assumptions using facts. You will master measurement techniques, sampling methods, and data collection plans that provide reliable data for decision-making.

Process Mapping

Make the invisible visible before fixing it. You will create current-state process maps, swimlane diagrams, and value stream maps that expose bottlenecks and non-value-added steps.

Root Cause Analysis

Stop treating symptoms and solve real problems. You will use tools like 5 Whys, Fishbone Diagrams, and Pareto Analysis to identify the true underlying causes - not just quick fixes.

Basic Statistical Analysis

Understand what your data is actually saying. You will learn process capability calculations, control chart interpretation, and descriptive statistical analysis for performance evaluation.

DMAIC Methodology

Follow a proven framework instead of random trial-and-error. You will learn to structure improvement initiatives using Define, Measure, Analyze, Improve, and Control phases for sustainable results.

Who This Program Is For

Operations Coordinators

Quality Analysts

Process Associates

Team Leaders

Junior Project Managers

Entry-Level Consultants

If you lead projects and meet PMI's mandatory experience requirements, this program is engineered to get you certified.

LSSYB Certification Training Program Roadmap Wheaton, IL

Why get LSSYB-certified?

Stop being overlooked for improvement teams

Get selected for high-visibility projects that demonstrate measurable business impact to leadership.

Position yourself for the Green Belt track

Yellow Belt is your launchpad - master the fundamentals and create a clear path to advanced roles and higher compensation.

Speak the language of operational excellence

Understand the tools, terminology, and mindset that quality and process improvement teams use every day.

Eligibility & Prerequisites

The Lean Six Sigma Yellow Belt is intentionally designed as the starting point for professionals entering the world of process improvement. Unlike advanced belts, it does not require prior project experience or technical background. It provides the foundational mindset, tools, and framework needed before progressing to Green Belt and beyond.

No Formal Education Requirements: There are no mandatory degree or diploma qualifications required to enroll in or earn a Yellow Belt certification.

No Prior Six Sigma Experience Needed: This certification is ideal for beginners and those newly stepping into operational excellence or continuous improvement environments.

Training Completion Recommended: While some certifying bodies allow direct exam attempts, completing a recognized training program (like ours) significantly improves exam success and real-world application capability.

Workplace Relevance: Most impactful for professionals in operations, quality, manufacturing, service delivery, business support, or anyone transitioning into process improvement roles.

Course Modules & Curriculum

Lesson 1: Project Selection & Charter Development

Learn to identify high-impact improvement opportunities using prioritization tools. Develop clear and measurable project charters, including problem statements, goals, scope boundaries, and stakeholder identification - essential skills for launching aligned and achievable improvement initiatives.

Lesson 2: Voice of the Customer (VOC)

Master methods for gathering and analyzing customer feedback. Translate needs and expectations into Critical-to-Quality (CTQ) requirements, and learn how to differentiate explicit requests from deeper underlying needs that influence satisfaction.

Lesson 3: Process Identification & High-Level Mapping

Create SIPOC diagrams to clarify process boundaries and relationships. Build high-level process maps to visualize how work flows, identify bottlenecks, and uncover inefficiencies before diving deeper into analysis.

Lesson 1: Data Collection Fundamentals

Understand the difference between continuous and discrete data and when each is applicable. Develop reliable operational definitions, sampling strategies, and data collection plans that eliminate ambiguity and ensure trustworthy measurement.

Lesson 2: Process Performance Metrics

Learn key Six Sigma performance metrics, including DPU, DPMO, yield, cycle time, and process capability indices (Cp, Cpk). Understand what these metrics reveal about customer satisfaction and process stability.

Lesson 3: Basic Measurement System Analysis

Establish measurement reliability before analysis. Learn the concepts of accuracy, precision, bias, and stability, and perform basic Gage R&R studies to verify that data is valid and repeatable.

Lesson 1: Process Mapping & Value Stream Analysis

Create detailed process maps and swimlane diagrams to visualize workflows and handoffs. Use value stream mapping to classify activities as value-added or non-value-added and identify improvement opportunities.

Lesson 2: Root Cause Analysis Tools

Apply structured techniques such as the 5 Whys, Fishbone (Ishikawa) Diagrams, and Pareto Analysis to move beyond treating symptoms and uncover the true underlying causes of process problems.

Lesson 3: Basic Statistical Analysis

Learn to calculate and interpret descriptive statistics such as mean, standard deviation, and range. Create and analyze histograms, run charts, and basic control charts to understand process behavior and variation patterns over time.

Lesson 1: Solution Generation & Implementation

Use structured brainstorming and prioritization frameworks to identify effective improvement ideas. Develop implementation plans with defined ownership, timelines, and success criteria to drive meaningful results.

Lesson 2: Control Phase & Sustainability

Create control plans to maintain improvements over time. Learn monitoring methods, documentation practices, and standard work procedures to prevent regression and ensure long-term stability.

Lesson 3: Lean Principles & Waste Elimination

Master the 8 wastes (DOWNTIME) and learn how to identify and eliminate them. Apply 5S principles for workplace organization and explore pull systems, Kanban, and continuous flow as alternatives to traditional batch processing.