Six Sigma Green Belt Training Program Milwaukee, WI

Your Six Sigma Green Belt Certification isn't just a certificate - it's the mark of true project leadership. Many professionals working in quality, operations, or process improvement roles face challenges in proving their capability because they lack formal Six Sigma Green Belt certification. You may already see inefficiencies, delays, and defects in your processes, but without the structured tools and statistical methods of Six Sigma, your ideas often sound like opinions rather than data-driven insights. On the other hand, Six Sigma Green Belt certified professionals lead improvement projects with confidence, apply analytical thinking to identify root causes, and deliver measurable cost savings that earn them promotions, recognition, and salaries up to 30% higher. The difference lies not in intelligence, but in structured problem-solving - and that's exactly what this program delivers. This Six Sigma Green Belt Course is not a theoretical statistics class filled with jargon. It is a practical, hands-on program built by experienced Black Belts and Master Black Belts who have led hundreds of successful projects across Milwaukee, WImanufacturing, IT services, and healthcare. They know that real-world organizations have constraints - limited budgets, tight timelines, and complex politics - and they've designed this Six Sigma Green Belt Certification Training to prepare you to handle exactly that. You'll learn how to apply the DMAIC methodology to define improvement goals, measure process performance using data, analyze results to find true root causes, implement sustainable solutions, and establish control mechanisms that prevent problems from returning. Unlike generic training programs, this six sigma green belt certification online course integrates tools, techniques, and strategy into a complete learning experience. You won't just memorize statistical terms; you'll learn to communicate results with clarity and confidence, translating technical findings into business impact that your management understands. By the end of this training, you'll not only hold a globally recognized Six Sigma Green Belt certification but also possess the competence to lead your first improvement project independently - from identifying opportunities to presenting measurable savings to your leadership team. Designed for working professionals in operations, manufacturing, quality, and services, this program offers flexible weekend and evening batches, with every session conducted live and recorded for your convenience. The six sigma green belt certification cost is structured to make professional upskilling affordable, while still maintaining premium-quality training and one-on-one mentorship. You'll get access to real project templates, Minitab practice exercises, control plan formats, and 24/7 support from certified Black Belts. What makes this program unique is its emphasis on guided project execution - most training providers leave you once the theory is over, but we stay with you until your Green Belt project is completed successfully. Earning your Six Sigma Green Belt Certification is more than an academic milestone - it's a professional transformation. It gives you the tools to solve problems scientifically, lead cross-functional teams, and demonstrate quantifiable improvements in cost, quality, and efficiency. Whether you're looking to boost your six sigma green belt salary, prepare for Black Belt certification, or secure leadership positions in process excellence, this program equips you with the practical skills and global credibility to get there. Enroll now in our Six Sigma Green Belt Certification Training and take your first confident step toward becoming a data-driven project leader.

Six Sigma Green Belt Training Course Highlights Milwaukee, WI

Accredited Training Provider

Learn with confidence knowing your training program meets international Six Sigma Body of Knowledge standards and is recognized by employers globally.

Taught by Certified Black Belts

Unlock your potential with expert instructors who are certified Six Sigma Black Belts with real-world project leadership experience across multiple industries.

Flexible Learning Schedule

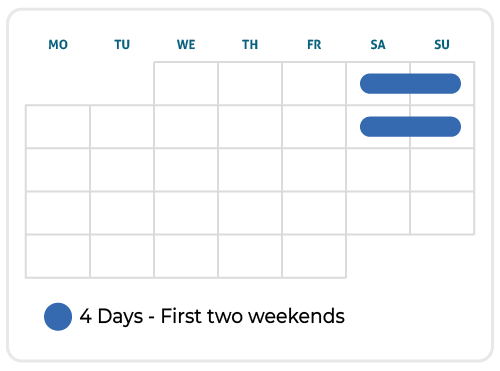

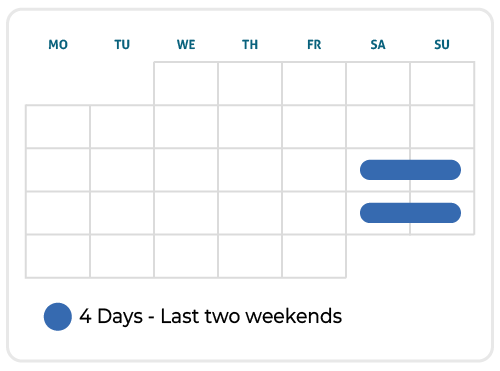

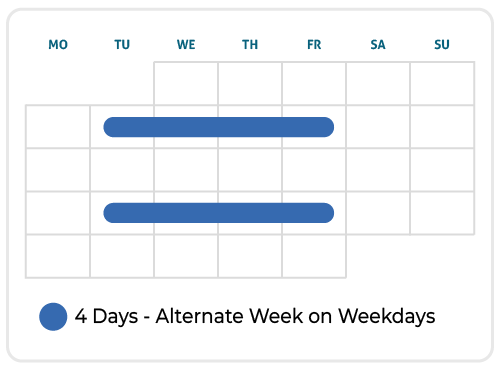

Balance certification with your current job by choosing from weekday-evening sessions, weekend-only batches, or an intensive 5-day immersive bootcamp.

Hands-On Project Training

Master the concepts through real data analysis, not just theory, with guided DMAIC project work and statistical software practice sessions.

Complete Statistical Toolkit

Gain proficiency with industry-standard tools including Minitab software access, process mapping templates, and comprehensive calculation guides.

24/7 Expert Support Network

Certified Black Belt instructors are available around the clock to resolve your statistical doubts and methodology questions.

Corporate Training

Ready to transform your team?

Get a custom quote for your organization's training needs.

Upcoming Schedule

Skills You Will Gain In Our Six Sigma Green Belt Training Program

Statistical Process Control (SPC)

Stop guessing whether your process is stable or drifting. Learn how to build and interpret control charts, recognize variation patterns, and distinguish between common cause and special cause variation so you know exactly when to intervene and when to maintain normal operations.

Root Cause Analysis

End the cycle of treating symptoms instead of real issues. Master analysis tools such as fishbone diagrams, 5 Whys, and hypothesis testing to uncover and eliminate the true drivers of defects and variation in your processes.

Process Capability Analysis

Understand whether your process can actually meet customer requirements before investing in improvement. Learn how to calculate and interpret Cp, Cpk, and other capability indices to assess process performance and customer satisfaction impact.

Design of Experiments (DOE)

Stop adjusting one variable at a time and hoping for the best. Learn factorial and advanced experimental design techniques that reveal interaction effects and allow you to optimize multiple factors simultaneously - reducing project duration and increasing results.

Lean Integration

Realize that waste elimination is as important as variation reduction. Learn to identify the eight wastes, create value stream maps, and integrate Lean methodology with Six Sigma for complete operational and process improvement.

Project Management for Improvement

Technical skills alone are not enough. Develop frameworks for stakeholder coordination, handling resistance to change, and benefit measurement to ensure your improvements are adopted, sustained, and deliver real ROI.

Who This Program Is For

Quality Engineers

Process Improvement Specialists

Operations Managers

Manufacturing Supervisors

Business Analysts

Project Managers

If you lead projects and meet PMI's mandatory experience requirements, this program is engineered to get you certified.

Six Sigma Green Belt Certification Training Program Roadmap

Why get Six Sigma Green Belt-certified?

Stop Being Invisible to Recruiters

Get past HR filters and land interviews for quality management and process improvement roles that match your experience.

Quantify Your Professional Value

Show documented ROI through measurable cost savings and defect reduction that translates directly into bonuses and promotions.

Shift from Firefighting to Strategic Leadership

Move beyond reacting to problems and start preventing them using data-driven process design and statistical control.

Eligibility & Prerequisites

Unlike PMP, the Six Sigma Green Belt certification does not enforce strict experience prerequisites through a governing body. However, that does not mean it is suitable for everyone. To be effective as a Green Belt, you should have certain foundational capabilities in place before pursuing the credential.

Basic Statistical Understanding: You don't need advanced mathematics, but you should be comfortable with foundational concepts like mean, standard deviation, and probability. If terms like "normal distribution" feel overwhelming, the coursework will be challenging.

Operational Process Exposure: This credential is intended for professionals who work within real business processes. If you have never documented workflows, collected process data, or participated in improvement initiatives, the methodology may not connect meaningfully.

Project Completion Requirement (Varies by Certification Body): Some certifying organizations require candidates to complete and present an actual DMAIC improvement project. Our training includes a guided, full-scale project simulation designed to satisfy this requirement for most bodies.

Certification Body Differences (ASQ, IASSC, Others): Each organization has unique eligibility, exam patterns, and evaluation criteria. Refer to our detailed FAQ section for a clear, side-by-side breakdown of requirements before selecting your certification path.

Course Modules & Curriculum

Lesson 1: Measurement System Analysis (MSA)

Ensure your data can be trusted before making decisions. Conduct Gage R&R studies to determine whether your measurement system is detecting real variation or simply noise. Establish data reliability before progressing in the DMAIC cycle.

Lesson 2: Process Capability & Performance Metrics

Assess how well your process meets customer specifications by calculating and interpreting capability indices including Cp, Cpk, Pp, and Ppk. Understand how capability results guide the urgency and scope of improvement interventions.

Lesson 3: Data Collection Strategy & Sampling

Create efficient data collection systems that reflect process reality without unnecessary effort. Apply sampling principles, differentiate continuous vs. discrete data, and use stratification to uncover meaningful variation patterns.

Lesson 1: Descriptive Statistics & Graphical Analysis

Visualize and interpret process behavior using histograms, boxplots, and scatter diagrams. Learn when to use mean, median, or mode and how to detect outliers that may require deeper investigation.

Lesson 2: Hypothesis Testing & Inferential Statistics

Determine whether observed differences in your process are statistically meaningful. Apply t-tests, ANOVA, and chi-square testing while understanding p-values, confidence intervals, and error risks.

Lesson 3: Correlation, Regression & Root Cause Identification

Quantify relationships between variables using correlation and regression analysis. Learn to avoid the common mistake of assuming correlation implies causation and focus on true drivers of variation.

Lesson 1: Design of Experiments (DOE) Fundamentals

Replace trial-and-error improvement techniques with data-driven factor testing. Implement factorial experiment designs to identify interactions between variables and optimize performance faster and more accurately.

Lesson 2: Lean Tools & Waste Elimination

Reduce inefficiency by identifying and eliminating the eight types of waste (DOWNTIME). Integrate Lean principles alongside Six Sigma to achieve simultaneous quality and efficiency improvement.

Lesson 3: Solution Selection & Pilot Testing

Evaluate solution alternatives based on cost, feasibility, risk, and projected impact. Conduct controlled pilot tests and validate results before full-scale implementation.

Lesson 1: Statistical Process Control (SPC) Charts

Use control charts to differentiate normal variation from signals requiring corrective action. Apply X-bar & R, I-MR, p-, and c-charts appropriately and use Western Electric rules to detect instability.

Lesson 2: Control Plans & Process Documentation

Create practical control plans that sustain improvements over time. Document key process parameters, ownership accountability, monitoring methods, and standard operating procedures (SOPs) that frontline users will actually follow.

Lesson 3: Change Management & Benefit Realization

Ensure improvements are adopted and maintained through stakeholder engagement, training, and clear accountability. Track and communicate project financial benefits to demonstrate organizational value and reinforce credibility.