Quick Enquiry Form

Categories

- Agile and Scrum (153)

- Business Analysis (53)

- Cirtix Client Administration (24)

- Cisco (29)

- Cloud Technology (25)

- Cyber Security (4)

- Data Science and Business Intelligence (3)

- DevOps (11)

- Digital Marketing (20)

- Emerging Technology (117)

- IT Service Management (51)

- Microsoft (28)

- Other (385)

- Project Management (431)

- Quality Management (84)

- salesforce (34)

Latest posts

Exploring the COBIT Framework..

10 Innovative Machine Learning Projects..

Microsoft Surface Devices for Hybrid..

Free Resources

Subscribe to Newsletter

CTFL Certification: Benefits for Developers and Managers

In today's competitive job market, having a CTFL certification can significantly boost your career prospects as a developer or manager. The Certified Tester Foundation Level (CTFL) certification is a globally recognized credential that demonstrates your expertise in software testing. In this article, we will explore the benefits of CTFL certification for both developers and managers, as well as the process of obtaining this valuable credential.

Benefits of CTFL Certification

-

Enhanced Skills: CTFL certification equips you with the essential skills and knowledge required to excel in software testing. This includes understanding different testing techniques, tools, and methodologies.

-

Career Advancement: Holding a CTFL certification can open up new job opportunities and help you advance in your career. Employers often prefer candidates with relevant certifications, as it demonstrates their commitment to professional development.

-

Increased Credibility: CTFL certification enhances your credibility as a software testing professional. It shows that you have met the rigorous standards set by the International Software Testing Qualifications Board (ISTQB).

-

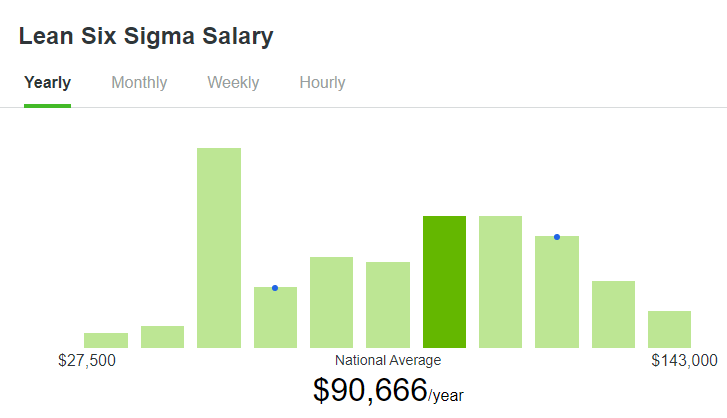

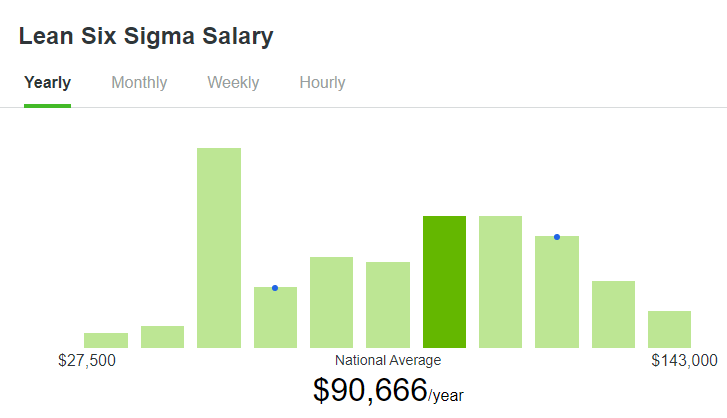

Higher Salary: Certified professionals typically command higher salaries than their non-certified counterparts. CTFL certification can lead to increased earning potential and better job prospects.

CTFL Certification for Developers

For developers, CTFL certification offers several advantages. It provides a solid foundation in software testing principles and practices, helping developers to deliver high-quality code. By understanding the importance of testing early in the development process, developers can identify and fix issues more efficiently, resulting in a more robust and reliable product.

CTFL Certification for Managers

Managers who hold a CTFL certification can effectively lead their teams and ensure the successful completion of testing projects. They have the knowledge and skills needed to make informed decisions about testing strategies, resource allocation, and risk management. CTFL certification also allows managers to communicate more effectively with their technical teams, fostering collaboration and innovation.

CTFL Exam and Syllabus

The CTFL exam covers a wide range of topics related to software testing, including testing principles, test design techniques, and test management. It assesses your understanding of key concepts and your ability to apply them in real-world scenarios. The exam is administered by accredited training providers and consists of multiple-choice questions.

The CTFL syllabus includes the following areas:

-

Fundamentals of software testing

-

Testing levels and types

-

Static testing

-

Test design techniques

-

Test management

-

Tools support for testing

How to Get CTFL Certification

To obtain CTFL certification, you must pass the official exam administered by an accredited training provider. It is recommended to prepare for the exam by studying the CTFL syllabus and using practice tests to assess your knowledge. Once you pass the exam, you will receive your certification, which is valid for life.

How to obtain CTFL Certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion

In conclusion, CTFL certification offers numerous benefits for developers and managers alike. It enhances your skills, opens up new career opportunities, and increases your credibility in the field of software testing. Whether you are looking to advance your career or improve your team's testing capabilities, CTFL certification is a valuable asset that can help you achieve your goals.

Contact Us :

Contact Us For More Information:

Visit :www.icertglobal.com Email : info@icertglobal.com

Read More

In today's competitive job market, having a CTFL certification can significantly boost your career prospects as a developer or manager. The Certified Tester Foundation Level (CTFL) certification is a globally recognized credential that demonstrates your expertise in software testing. In this article, we will explore the benefits of CTFL certification for both developers and managers, as well as the process of obtaining this valuable credential.

Benefits of CTFL Certification

-

Enhanced Skills: CTFL certification equips you with the essential skills and knowledge required to excel in software testing. This includes understanding different testing techniques, tools, and methodologies.

-

Career Advancement: Holding a CTFL certification can open up new job opportunities and help you advance in your career. Employers often prefer candidates with relevant certifications, as it demonstrates their commitment to professional development.

-

Increased Credibility: CTFL certification enhances your credibility as a software testing professional. It shows that you have met the rigorous standards set by the International Software Testing Qualifications Board (ISTQB).

-

Higher Salary: Certified professionals typically command higher salaries than their non-certified counterparts. CTFL certification can lead to increased earning potential and better job prospects.

CTFL Certification for Developers

For developers, CTFL certification offers several advantages. It provides a solid foundation in software testing principles and practices, helping developers to deliver high-quality code. By understanding the importance of testing early in the development process, developers can identify and fix issues more efficiently, resulting in a more robust and reliable product.

CTFL Certification for Managers

Managers who hold a CTFL certification can effectively lead their teams and ensure the successful completion of testing projects. They have the knowledge and skills needed to make informed decisions about testing strategies, resource allocation, and risk management. CTFL certification also allows managers to communicate more effectively with their technical teams, fostering collaboration and innovation.

CTFL Exam and Syllabus

The CTFL exam covers a wide range of topics related to software testing, including testing principles, test design techniques, and test management. It assesses your understanding of key concepts and your ability to apply them in real-world scenarios. The exam is administered by accredited training providers and consists of multiple-choice questions.

The CTFL syllabus includes the following areas:

-

Fundamentals of software testing

-

Testing levels and types

-

Static testing

-

Test design techniques

-

Test management

-

Tools support for testing

How to Get CTFL Certification

To obtain CTFL certification, you must pass the official exam administered by an accredited training provider. It is recommended to prepare for the exam by studying the CTFL syllabus and using practice tests to assess your knowledge. Once you pass the exam, you will receive your certification, which is valid for life.

How to obtain CTFL Certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion

In conclusion, CTFL certification offers numerous benefits for developers and managers alike. It enhances your skills, opens up new career opportunities, and increases your credibility in the field of software testing. Whether you are looking to advance your career or improve your team's testing capabilities, CTFL certification is a valuable asset that can help you achieve your goals.

Contact Us :

Contact Us For More Information:

Visit :www.icertglobal.com Email : info@icertglobal.com

Overcoming Challenges in Lean Management Implementation

Lean management is a highly effective approach to streamlining processes and increasing efficiency within an organization. However, implementing lean practices can pose various challenges for businesses. In this article, we will explore the obstacles that organizations face when trying to adopt lean management and provide strategies for overcoming these challenges to achieve lean success.

Understanding Lean Management

Before diving into the challenges of lean management implementation, it is essential to understand what lean management entails. Lean management is a methodology that focuses on eliminating waste, reducing costs, and improving overall productivity. By identifying and removing inefficiencies in processes, organizations can become more agile and competitive in today's fast-paced business environment.

Common Obstacles in Lean Implementation

-

Lack of Leadership Commitment: One of the most significant barriers to successful lean implementation is a lack of buy-in from top management. Without strong leadership support, it can be challenging to drive the necessary changes throughout the organization.

-

Resistance to Change: Employees may resist adopting lean practices due to fear of the unknown or concerns about job security. Overcoming this resistance requires effective communication and clear explanations of how lean principles will benefit both the organization and its employees.

-

Lack of Training and Education: Implementing lean practices requires a shift in mindset and a new way of working. Without adequate training and education, employees may struggle to understand and implement lean principles effectively.

-

Inadequate Resources: Lean implementation may require investments in new technology, training programs, or process improvements. Limited resources can hinder the successful adoption of lean practices.

Strategies for Overcoming Lean Management Challenges

-

Leadership Involvement: Engage senior leaders in the lean implementation process to demonstrate their commitment and support. Leadership involvement can help drive change and create a culture of continuous improvement.

-

Employee Involvement: Involve employees at all levels in the lean implementation process. Seek their input, feedback, and ideas for improving processes. By engaging employees in the change process, you can increase buy-in and ownership of lean practices.

-

Training and Development: Provide employees with the training and education they need to understand lean principles and how to apply them in their daily work. Invest in continuous learning to ensure that employees have the skills and knowledge to support lean initiatives.

-

Resource Allocation: Allocate resources strategically to support lean implementation efforts. Identify and address any gaps in resources, whether it be funding, technology, or expertise, to ensure the successful adoption of lean practices.

How to obtain Lean Management certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion

By addressing the challenges of lean management implementation head-on and implementing the strategies outlined above, organizations can overcome obstacles and achieve lean success. Lean practices can help businesses improve efficiency, reduce costs, and deliver value to customers. With the right approach and commitment from all levels of the organization, lean management can transform operations and drive sustainable growth.

Contact Us For More Information :

Visit : www.icertglobal.com Email : info@icertglobal.com

Read More

Lean management is a highly effective approach to streamlining processes and increasing efficiency within an organization. However, implementing lean practices can pose various challenges for businesses. In this article, we will explore the obstacles that organizations face when trying to adopt lean management and provide strategies for overcoming these challenges to achieve lean success.

Understanding Lean Management

Before diving into the challenges of lean management implementation, it is essential to understand what lean management entails. Lean management is a methodology that focuses on eliminating waste, reducing costs, and improving overall productivity. By identifying and removing inefficiencies in processes, organizations can become more agile and competitive in today's fast-paced business environment.

Common Obstacles in Lean Implementation

-

Lack of Leadership Commitment: One of the most significant barriers to successful lean implementation is a lack of buy-in from top management. Without strong leadership support, it can be challenging to drive the necessary changes throughout the organization.

-

Resistance to Change: Employees may resist adopting lean practices due to fear of the unknown or concerns about job security. Overcoming this resistance requires effective communication and clear explanations of how lean principles will benefit both the organization and its employees.

-

Lack of Training and Education: Implementing lean practices requires a shift in mindset and a new way of working. Without adequate training and education, employees may struggle to understand and implement lean principles effectively.

-

Inadequate Resources: Lean implementation may require investments in new technology, training programs, or process improvements. Limited resources can hinder the successful adoption of lean practices.

Strategies for Overcoming Lean Management Challenges

-

Leadership Involvement: Engage senior leaders in the lean implementation process to demonstrate their commitment and support. Leadership involvement can help drive change and create a culture of continuous improvement.

-

Employee Involvement: Involve employees at all levels in the lean implementation process. Seek their input, feedback, and ideas for improving processes. By engaging employees in the change process, you can increase buy-in and ownership of lean practices.

-

Training and Development: Provide employees with the training and education they need to understand lean principles and how to apply them in their daily work. Invest in continuous learning to ensure that employees have the skills and knowledge to support lean initiatives.

-

Resource Allocation: Allocate resources strategically to support lean implementation efforts. Identify and address any gaps in resources, whether it be funding, technology, or expertise, to ensure the successful adoption of lean practices.

How to obtain Lean Management certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion

By addressing the challenges of lean management implementation head-on and implementing the strategies outlined above, organizations can overcome obstacles and achieve lean success. Lean practices can help businesses improve efficiency, reduce costs, and deliver value to customers. With the right approach and commitment from all levels of the organization, lean management can transform operations and drive sustainable growth.

Contact Us For More Information :

Visit : www.icertglobal.com Email : info@icertglobal.com

Advantages of QMS Certification for Your Company

In today's competitive business environment, implementing a Quality Management System (QMS) and obtaining certification can provide numerous benefits to your company. From improved processes to increased customer satisfaction, QMS certification can help streamline your operations and drive business growth. Let's explore some of the key advantages of QMS certification for your company:

Enhanced Company Efficiency

One of the primary benefits of QMS certification is the improved efficiency of your company's operations. By implementing a quality management system, you can standardize processes, reduce errors, and ensure consistent quality across all areas of your business. This systematic approach not only increases productivity but also helps your company operate more effectively and efficiently.

Improved Customer Satisfaction

Customer satisfaction is paramount in today's business world, and QMS certification can help you meet and exceed customer expectations. By focusing on quality control, reducing errors, and continuously improving your processes, you can enhance the overall customer experience and build customer loyalty. This, in turn, can lead to increased customer retention and more repeat business.

Compliance Requirements and Risk Management

In many industries, compliance with regulatory requirements is essential for business success. QMS certification can help ensure that your company meets all necessary compliance standards and mitigates risks. By identifying and addressing potential risks through proactive measures such as internal audits and corrective actions, you can protect your company from costly mistakes and legal issues.

Competitive Advantage and Business Growth

Obtaining QMS certification can give your company a competitive edge in the marketplace. By demonstrating your commitment to quality and continuous improvement, you can differentiate your brand from competitors and attract new customers. This enhanced reputation can help drive business growth and open up new opportunities for expansion and market differentiation.

Leadership Buy-in and Employee Engagement

Successful implementation of a QMS requires strong leadership buy-in and employee engagement at all levels of the organization. By involving employees in the certification process, you can create a culture of quality and innovation within your company. This can lead to improved performance, increased morale, and a more cohesive organizational structure.

Sustainability Practices and Innovation Culture

QMS certification can also help your company incorporate sustainability practices and foster an innovation culture. By focusing on resource optimization, traceability, and stakeholder satisfaction, you can build a reputation for environmental responsibility and commitment to social good. This can attract like-minded customers and partners and drive innovation within your industry.

How to obtain Quality Management certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion

In conclusion, QMS certification offers numerous advantages for your company, from enhanced efficiency and customer satisfaction to competitive advantage and business growth. By investing in a quality management system and obtaining certification, you can position your company for long-term success and sustainable growth in today's ever-changing business landscape.

Contact Us For More Information :

Visit : www.icertglobal.com Email : info@icertglobal.com

Read More

In today's competitive business environment, implementing a Quality Management System (QMS) and obtaining certification can provide numerous benefits to your company. From improved processes to increased customer satisfaction, QMS certification can help streamline your operations and drive business growth. Let's explore some of the key advantages of QMS certification for your company:

Enhanced Company Efficiency

One of the primary benefits of QMS certification is the improved efficiency of your company's operations. By implementing a quality management system, you can standardize processes, reduce errors, and ensure consistent quality across all areas of your business. This systematic approach not only increases productivity but also helps your company operate more effectively and efficiently.

Improved Customer Satisfaction

Customer satisfaction is paramount in today's business world, and QMS certification can help you meet and exceed customer expectations. By focusing on quality control, reducing errors, and continuously improving your processes, you can enhance the overall customer experience and build customer loyalty. This, in turn, can lead to increased customer retention and more repeat business.

Compliance Requirements and Risk Management

In many industries, compliance with regulatory requirements is essential for business success. QMS certification can help ensure that your company meets all necessary compliance standards and mitigates risks. By identifying and addressing potential risks through proactive measures such as internal audits and corrective actions, you can protect your company from costly mistakes and legal issues.

Competitive Advantage and Business Growth

Obtaining QMS certification can give your company a competitive edge in the marketplace. By demonstrating your commitment to quality and continuous improvement, you can differentiate your brand from competitors and attract new customers. This enhanced reputation can help drive business growth and open up new opportunities for expansion and market differentiation.

Leadership Buy-in and Employee Engagement

Successful implementation of a QMS requires strong leadership buy-in and employee engagement at all levels of the organization. By involving employees in the certification process, you can create a culture of quality and innovation within your company. This can lead to improved performance, increased morale, and a more cohesive organizational structure.

Sustainability Practices and Innovation Culture

QMS certification can also help your company incorporate sustainability practices and foster an innovation culture. By focusing on resource optimization, traceability, and stakeholder satisfaction, you can build a reputation for environmental responsibility and commitment to social good. This can attract like-minded customers and partners and drive innovation within your industry.

How to obtain Quality Management certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion

In conclusion, QMS certification offers numerous advantages for your company, from enhanced efficiency and customer satisfaction to competitive advantage and business growth. By investing in a quality management system and obtaining certification, you can position your company for long-term success and sustainable growth in today's ever-changing business landscape.

Contact Us For More Information :

Visit : www.icertglobal.com Email : info@icertglobal.com

Online vs. In-Person MINITAB Certification: Pros and Cons

Are you considering getting certified in MINITAB, but unsure whether to pursue online certification or attend in-person training? Let's break down the pros and cons of each option to help you make an informed decision.

MINITAB Certification Online

Pros:

-

Convenience: Online MINITAB certification allows you to study and complete the course at your own pace and schedule.

-

Cost-Effective: Online courses are often more affordable than in-person training, saving you money on travel and accommodation expenses.

-

Flexibility: You can access online resources from anywhere in the world, giving you the flexibility to learn from the comfort of your own home.

-

Self-Paced Learning: Online courses allow you to review materials at your own pace and focus on areas that need more attention.

Cons:

-

Lack of Hands-On Experience: Online certification may lack hands-on experience and practical application of MINITAB skills.

-

Limited Interaction: You may have limited interaction with instructors and other students in an online setting, leading to potential difficulties in clarifying doubts.

MINITAB Certification In-Person

Pros:

-

Hands-On Experience: In-person training provides hands-on experience and practical application of MINITAB skills.

-

Interactive Learning: In-person training allows for real-time interaction with instructors and other students, promoting a better understanding of the material.

-

Networking Opportunities: Attending in-person training sessions can help you build a professional network within the MINITAB community.

Cons:

-

Time-Costly: In-person training may require you to take time off work or travel to attend sessions, which can be time-consuming and costly.

-

Higher Costs: In-person training is often more expensive than online certification due to additional expenses such as travel and accommodation.

MINITAB Certification Comparison

Online MINITAB Certification:

-

Convenient

-

Cost-effective

-

Flexible

-

Self-paced learning

In-Person MINITAB Certification:

-

Hands-on experience

-

Interactive learning

-

Networking opportunities

-

Time-costly

How to obtain MINITAB certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion

In conclusion, whether you choose online or in-person MINITAB certification depends on your preferences, learning style, and budget. Online certification offers flexibility and cost-effectiveness, while in-person training provides hands-on experience and networking opportunities. Consider your priorities and choose the option that aligns best with your goals and resources.

Read More

Are you considering getting certified in MINITAB, but unsure whether to pursue online certification or attend in-person training? Let's break down the pros and cons of each option to help you make an informed decision.

MINITAB Certification Online

Pros:

-

Convenience: Online MINITAB certification allows you to study and complete the course at your own pace and schedule.

-

Cost-Effective: Online courses are often more affordable than in-person training, saving you money on travel and accommodation expenses.

-

Flexibility: You can access online resources from anywhere in the world, giving you the flexibility to learn from the comfort of your own home.

-

Self-Paced Learning: Online courses allow you to review materials at your own pace and focus on areas that need more attention.

Cons:

-

Lack of Hands-On Experience: Online certification may lack hands-on experience and practical application of MINITAB skills.

-

Limited Interaction: You may have limited interaction with instructors and other students in an online setting, leading to potential difficulties in clarifying doubts.

MINITAB Certification In-Person

Pros:

-

Hands-On Experience: In-person training provides hands-on experience and practical application of MINITAB skills.

-

Interactive Learning: In-person training allows for real-time interaction with instructors and other students, promoting a better understanding of the material.

-

Networking Opportunities: Attending in-person training sessions can help you build a professional network within the MINITAB community.

Cons:

-

Time-Costly: In-person training may require you to take time off work or travel to attend sessions, which can be time-consuming and costly.

-

Higher Costs: In-person training is often more expensive than online certification due to additional expenses such as travel and accommodation.

MINITAB Certification Comparison

Online MINITAB Certification:

-

Convenient

-

Cost-effective

-

Flexible

-

Self-paced learning

In-Person MINITAB Certification:

-

Hands-on experience

-

Interactive learning

-

Networking opportunities

-

Time-costly

How to obtain MINITAB certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion

In conclusion, whether you choose online or in-person MINITAB certification depends on your preferences, learning style, and budget. Online certification offers flexibility and cost-effectiveness, while in-person training provides hands-on experience and networking opportunities. Consider your priorities and choose the option that aligns best with your goals and resources.

Integrating Lean Six Sigma with Agile and Scrum Methodologies

In today's rapidly evolving business landscape, organizations are constantly seeking ways to improve their operational efficiency and deliver value to their customers. Two popular methodologies that have gained significant traction in recent years are Lean Six Sigma and Agile/Scrum. While these methodologies originated in different industries and serve distinct purposes, they can be integrated to create a powerful framework for driving process improvement and delivering high-quality products and services.

What is Lean Six Sigma?

Lean Six Sigma is a methodology that combines the principles of Lean manufacturing and Six Sigma to eliminate waste, reduce variation, and improve overall quality in a systematic and data-driven manner. Lean focuses on streamlining processes and eliminating non-value-added activities, while Six Sigma aims to reduce defects and variation in processes to achieve near-perfect quality. By integrating the principles of Lean and Six Sigma, organizations can achieve significant improvements in efficiency, productivity, and customer satisfaction.

What is Agile and Scrum?

Agile is a project management methodology that emphasizes flexibility, adaptability, and collaboration in the development of software and other products. Scrum, on the other hand, is a specific framework within Agile that defines roles, activities, and artifacts to facilitate the iterative and incremental development of products. Agile and Scrum are well-suited for projects that require frequent changes, rapid delivery, and close collaboration between cross-functional teams.

Benefits of Integrating Lean Six Sigma with Agile and Scrum:

-

Improved process efficiency and quality

-

Faster delivery of products and services

-

Enhanced collaboration and communication between teams

-

Better alignment of project objectives with customer needs

-

Increased flexibility and adaptability to changing market conditions

-

Reduced waste and variation in processes

-

Continuous improvement culture that drives innovation and growth

How to Integrate Lean Six Sigma with Agile and Scrum:

Integrating Lean Six Sigma with Agile and Scrum requires a deep understanding of both methodologies and how they complement each other. Organizations can start by aligning Lean Six Sigma principles with Agile values, such as customer focus, continuous improvement, and empowerment of teams. By incorporating Lean Six Sigma tools and techniques into Agile/Scrum processes, organizations can identify and eliminate waste, reduce defects, and improve overall process efficiency.

Success Factors for Lean Six Sigma with Agile and Scrum:

-

Strong leadership support and commitment to process improvement

-

Cross-functional collaboration and communication

-

Training and certification in Lean Six Sigma and Agile/Scrum methodologies

-

Clear alignment of project objectives with customer needs

-

Regular monitoring and evaluation of process performance

-

Continuous learning and adaptation based on feedback and data

How to obtain Lean Six Sigma Black Belt certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion:

Integrating Lean Six Sigma with Agile and Scrum methodologies can provide organizations with a powerful framework for driving process improvement, delivering high-quality products and services, and achieving sustainable growth. By combining the principles of Lean Six Sigma with the flexibility and adaptability of Agile/Scrum, organizations can create a culture of continuous improvement, innovation, and customer-centricity that sets them apart in today's competitive marketplace.

Read More

In today's rapidly evolving business landscape, organizations are constantly seeking ways to improve their operational efficiency and deliver value to their customers. Two popular methodologies that have gained significant traction in recent years are Lean Six Sigma and Agile/Scrum. While these methodologies originated in different industries and serve distinct purposes, they can be integrated to create a powerful framework for driving process improvement and delivering high-quality products and services.

What is Lean Six Sigma?

Lean Six Sigma is a methodology that combines the principles of Lean manufacturing and Six Sigma to eliminate waste, reduce variation, and improve overall quality in a systematic and data-driven manner. Lean focuses on streamlining processes and eliminating non-value-added activities, while Six Sigma aims to reduce defects and variation in processes to achieve near-perfect quality. By integrating the principles of Lean and Six Sigma, organizations can achieve significant improvements in efficiency, productivity, and customer satisfaction.

What is Agile and Scrum?

Agile is a project management methodology that emphasizes flexibility, adaptability, and collaboration in the development of software and other products. Scrum, on the other hand, is a specific framework within Agile that defines roles, activities, and artifacts to facilitate the iterative and incremental development of products. Agile and Scrum are well-suited for projects that require frequent changes, rapid delivery, and close collaboration between cross-functional teams.

Benefits of Integrating Lean Six Sigma with Agile and Scrum:

-

Improved process efficiency and quality

-

Faster delivery of products and services

-

Enhanced collaboration and communication between teams

-

Better alignment of project objectives with customer needs

-

Increased flexibility and adaptability to changing market conditions

-

Reduced waste and variation in processes

-

Continuous improvement culture that drives innovation and growth

How to Integrate Lean Six Sigma with Agile and Scrum:

Integrating Lean Six Sigma with Agile and Scrum requires a deep understanding of both methodologies and how they complement each other. Organizations can start by aligning Lean Six Sigma principles with Agile values, such as customer focus, continuous improvement, and empowerment of teams. By incorporating Lean Six Sigma tools and techniques into Agile/Scrum processes, organizations can identify and eliminate waste, reduce defects, and improve overall process efficiency.

Success Factors for Lean Six Sigma with Agile and Scrum:

-

Strong leadership support and commitment to process improvement

-

Cross-functional collaboration and communication

-

Training and certification in Lean Six Sigma and Agile/Scrum methodologies

-

Clear alignment of project objectives with customer needs

-

Regular monitoring and evaluation of process performance

-

Continuous learning and adaptation based on feedback and data

How to obtain Lean Six Sigma Black Belt certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion:

Integrating Lean Six Sigma with Agile and Scrum methodologies can provide organizations with a powerful framework for driving process improvement, delivering high-quality products and services, and achieving sustainable growth. By combining the principles of Lean Six Sigma with the flexibility and adaptability of Agile/Scrum, organizations can create a culture of continuous improvement, innovation, and customer-centricity that sets them apart in today's competitive marketplace.

Future Trends in Lean Management

In today's fast-paced and ever-changing business environment, organizations are constantly seeking ways to streamline processes, reduce waste, and increase efficiency. Lean management has emerged as a popular approach to achieving these goals, but what does the future hold for this methodology? In this article, we will explore the future trends in lean management and how organizations can stay ahead of the curve.

Lean management is a philosophy that focuses on maximizing customer value while minimizing waste. It encompasses a set of principles, practices, and techniques aimed at improving processes and driving continuous improvement. As technology advances and business landscapes evolve, the future of lean management is taking on new dimensions. Let's delve into some of the key trends shaping the future of lean management.

Lean Production Techniques

One of the future trends in lean management is the adoption of advanced lean production techniques. As industry 4.0 continues to gain momentum, organizations are leveraging technology to optimize their production processes. From automation and robotics to data analytics and artificial intelligence, lean production techniques are becoming increasingly digitized and interconnected.

Agile Lean Management

Another future trend in lean management is the integration of agile principles. Agile lean management involves combining the flexibility and adaptability of agile methodologies with the efficiency and waste reduction of lean practices. By fostering a culture of continuous improvement and innovation, organizations can respond quickly to changing market dynamics and customer demands.

Lean Technology Adoption

The future of lean management also revolves around the adoption of cutting-edge technologies. From cloud computing and Internet of Things (IoT) to virtual reality and blockchain, organizations are embracing digital transformation to enhance their lean initiatives. By harnessing the power of technology, businesses can drive efficiencies, improve decision-making, and unlock new opportunities for growth.

Lean Culture and Leadership

Building a culture of lean thinking and empowering leadership is crucial for the success of lean management. In the future, organizations will need to focus on developing lean leadership capabilities, fostering a culture of continuous learning and improvement, and engaging employees at all levels in lean initiatives. By nurturing a lean culture, companies can drive sustainable change and achieve long-term success.

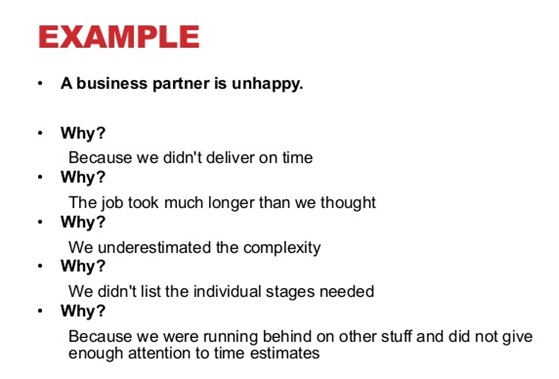

Lean Problem-Solving and Quality Management

Continuous improvement lies at the heart of lean management, and in the future, organizations will need to place greater emphasis on lean problem-solving and quality management. By adopting lean tools and techniques such as root cause analysis, value stream mapping, and Kaizen events, businesses can identify and address issues proactively, drive quality improvements, and enhance customer satisfaction.

Efficiency in Lean Management

Efficiency is a key tenet of lean management, and in the future, organizations will need to focus on optimizing their lean processes to maximize efficiency. By eliminating bottlenecks, reducing cycle times, and increasing productivity, companies can streamline operations, save costs, and deliver value to customers more effectively.

Lean Innovation and Development

Innovation is essential for staying competitive in today's market, and lean management can be a catalyst for driving innovation. In the future, organizations will need to foster a culture of experimentation, creativity, and risk-taking to spur lean innovation and development. By encouraging employees to think outside the box and embrace new ideas, businesses can differentiate themselves and create sustainable competitive advantages.

How to obtain Lean Management certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion

As organizations navigate the complexities of today's business landscape, the future of lean management holds immense promise. By embracing advanced production techniques, adopting agile principles, leveraging technology, building a culture of lean thinking, and focusing on problem-solving and quality management, businesses can drive continuous improvement, enhance efficiency, and achieve sustainable growth. The key to success lies in staying ahead of the curve, adapting to change, and constantly pushing the boundaries of what is possible with lean management.

Contact Us For More Information:

Visit :www.icertglobal.comEmail : info@icertglobal.com

Read More

In today's fast-paced and ever-changing business environment, organizations are constantly seeking ways to streamline processes, reduce waste, and increase efficiency. Lean management has emerged as a popular approach to achieving these goals, but what does the future hold for this methodology? In this article, we will explore the future trends in lean management and how organizations can stay ahead of the curve.

Lean management is a philosophy that focuses on maximizing customer value while minimizing waste. It encompasses a set of principles, practices, and techniques aimed at improving processes and driving continuous improvement. As technology advances and business landscapes evolve, the future of lean management is taking on new dimensions. Let's delve into some of the key trends shaping the future of lean management.

Lean Production Techniques

One of the future trends in lean management is the adoption of advanced lean production techniques. As industry 4.0 continues to gain momentum, organizations are leveraging technology to optimize their production processes. From automation and robotics to data analytics and artificial intelligence, lean production techniques are becoming increasingly digitized and interconnected.

Agile Lean Management

Another future trend in lean management is the integration of agile principles. Agile lean management involves combining the flexibility and adaptability of agile methodologies with the efficiency and waste reduction of lean practices. By fostering a culture of continuous improvement and innovation, organizations can respond quickly to changing market dynamics and customer demands.

Lean Technology Adoption

The future of lean management also revolves around the adoption of cutting-edge technologies. From cloud computing and Internet of Things (IoT) to virtual reality and blockchain, organizations are embracing digital transformation to enhance their lean initiatives. By harnessing the power of technology, businesses can drive efficiencies, improve decision-making, and unlock new opportunities for growth.

Lean Culture and Leadership

Building a culture of lean thinking and empowering leadership is crucial for the success of lean management. In the future, organizations will need to focus on developing lean leadership capabilities, fostering a culture of continuous learning and improvement, and engaging employees at all levels in lean initiatives. By nurturing a lean culture, companies can drive sustainable change and achieve long-term success.

Lean Problem-Solving and Quality Management

Continuous improvement lies at the heart of lean management, and in the future, organizations will need to place greater emphasis on lean problem-solving and quality management. By adopting lean tools and techniques such as root cause analysis, value stream mapping, and Kaizen events, businesses can identify and address issues proactively, drive quality improvements, and enhance customer satisfaction.

Efficiency in Lean Management

Efficiency is a key tenet of lean management, and in the future, organizations will need to focus on optimizing their lean processes to maximize efficiency. By eliminating bottlenecks, reducing cycle times, and increasing productivity, companies can streamline operations, save costs, and deliver value to customers more effectively.

Lean Innovation and Development

Innovation is essential for staying competitive in today's market, and lean management can be a catalyst for driving innovation. In the future, organizations will need to foster a culture of experimentation, creativity, and risk-taking to spur lean innovation and development. By encouraging employees to think outside the box and embrace new ideas, businesses can differentiate themselves and create sustainable competitive advantages.

How to obtain Lean Management certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion

As organizations navigate the complexities of today's business landscape, the future of lean management holds immense promise. By embracing advanced production techniques, adopting agile principles, leveraging technology, building a culture of lean thinking, and focusing on problem-solving and quality management, businesses can drive continuous improvement, enhance efficiency, and achieve sustainable growth. The key to success lies in staying ahead of the curve, adapting to change, and constantly pushing the boundaries of what is possible with lean management.

Contact Us For More Information:

Visit :www.icertglobal.comEmail : info@icertglobal.com

Obstacles for CTFL Candidates and Strategies to Overcome Them

Are you a Certified Tester Foundation Level (CTFL) candidate facing challenges in your exam preparation? Do you feel overwhelmed by the study material and unsure of how to navigate the certification process successfully? Rest assured, you are not alone. Many aspiring CTFL professionals encounter obstacles along their journey to certification. In this article, we will explore common obstacles faced by CTFL candidates and provide you with effective strategies to overcome them.

Obstacles for CTFL Candidates

CTFL Certification Challenges

One of the primary obstacles for CTFL candidates is the sheer volume of material that needs to be covered for the exam. The CTFL certification is comprehensive, covering a wide range of testing principles, terms, and techniques. As a result, candidates often feel daunted by the amount of information they need to learn and retain.

CTFL Exam Difficulties

Another obstacle that CTFL candidates face is the difficulty of the exam itself. The CTFL exam is designed to test candidates' understanding of software testing principles and practices. It requires critical thinking skills, as well as the ability to apply theoretical knowledge to practical scenarios. Many candidates struggle with the complexity of the exam questions and find it challenging to demonstrate their knowledge effectively.

CTFL Study Obstacles

Effective study habits are essential for success in the CTFL exam. However, some candidates struggle to create a study plan that works for them. They may have difficulty staying motivated, managing their time effectively, or finding resources that align with their learning style.

Strategies to Overcome Obstacles

Tips for Passing CTFL

To overcome the obstacles faced by CTFL candidates, it is essential to develop a strategic approach to exam preparation. Here are some tips for passing the CTFL exam successfully:

-

Create a study schedule and stick to it

-

Utilize a variety of study materials, such as textbooks, online resources, and practice exams

-

Engage in active learning techniques, such as note-taking and summarizing key concepts

-

Join a study group or online forum to discuss challenging topics with peers

How to Overcome CTFL Hurdles

In addition to the above tips, here are some specific strategies to help you overcome obstacles in your CTFL exam preparation:

-

Break down the study material into manageable chunks and focus on one topic at a time

-

Use mnemonic devices or visual aids to help you remember complex concepts

-

Practice problem-solving using past exam papers or sample questions to familiarize yourself with the exam format

-

Seek guidance from experienced CTFL professionals or mentors for study advice and support

CTFL Certification Tips

Achieving CTFL certification is a significant milestone in your career as a software tester. To increase your chances of success, consider the following certification tips:

-

Stay updated on the latest industry trends and developments in software testing

-

Participate in continuous professional development activities, such as attending workshops or conferences

-

Network with other testing professionals to exchange knowledge and best practices

-

Maintain a positive attitude and believe in your ability to succeed in the exam

How to obtain CTFL certification?

We are an Education Technology company providingcertification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion

In conclusion, while the road to CTFL certification may present obstacles for candidates, with the right strategies and mindset, these challenges can be overcome. By following the tips and techniques outlined in this article, you can navigate the certification process effectively and achieve success in your CTFL exam. Remember, persistence, dedication, and a proactive approach to studying are key to overcoming obstacles and achieving your certification goals. Good luck on your CTFL journey.

Contact Us For More Information:

Visit :www.icertglobal.comEmail : info@icertglobal.com

Read More

Are you a Certified Tester Foundation Level (CTFL) candidate facing challenges in your exam preparation? Do you feel overwhelmed by the study material and unsure of how to navigate the certification process successfully? Rest assured, you are not alone. Many aspiring CTFL professionals encounter obstacles along their journey to certification. In this article, we will explore common obstacles faced by CTFL candidates and provide you with effective strategies to overcome them.

Obstacles for CTFL Candidates

CTFL Certification Challenges

One of the primary obstacles for CTFL candidates is the sheer volume of material that needs to be covered for the exam. The CTFL certification is comprehensive, covering a wide range of testing principles, terms, and techniques. As a result, candidates often feel daunted by the amount of information they need to learn and retain.

CTFL Exam Difficulties

Another obstacle that CTFL candidates face is the difficulty of the exam itself. The CTFL exam is designed to test candidates' understanding of software testing principles and practices. It requires critical thinking skills, as well as the ability to apply theoretical knowledge to practical scenarios. Many candidates struggle with the complexity of the exam questions and find it challenging to demonstrate their knowledge effectively.

CTFL Study Obstacles

Effective study habits are essential for success in the CTFL exam. However, some candidates struggle to create a study plan that works for them. They may have difficulty staying motivated, managing their time effectively, or finding resources that align with their learning style.

Strategies to Overcome Obstacles

Tips for Passing CTFL

To overcome the obstacles faced by CTFL candidates, it is essential to develop a strategic approach to exam preparation. Here are some tips for passing the CTFL exam successfully:

-

Create a study schedule and stick to it

-

Utilize a variety of study materials, such as textbooks, online resources, and practice exams

-

Engage in active learning techniques, such as note-taking and summarizing key concepts

-

Join a study group or online forum to discuss challenging topics with peers

How to Overcome CTFL Hurdles

In addition to the above tips, here are some specific strategies to help you overcome obstacles in your CTFL exam preparation:

-

Break down the study material into manageable chunks and focus on one topic at a time

-

Use mnemonic devices or visual aids to help you remember complex concepts

-

Practice problem-solving using past exam papers or sample questions to familiarize yourself with the exam format

-

Seek guidance from experienced CTFL professionals or mentors for study advice and support

CTFL Certification Tips

Achieving CTFL certification is a significant milestone in your career as a software tester. To increase your chances of success, consider the following certification tips:

-

Stay updated on the latest industry trends and developments in software testing

-

Participate in continuous professional development activities, such as attending workshops or conferences

-

Network with other testing professionals to exchange knowledge and best practices

-

Maintain a positive attitude and believe in your ability to succeed in the exam

How to obtain CTFL certification?

We are an Education Technology company providingcertification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

-

Project Management: PMP, CAPM ,PMI RMP

-

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

-

Business Analysis: CBAP, CCBA, ECBA

-

Agile Training: PMI-ACP , CSM , CSPO

-

Scrum Training: CSM

-

DevOps

-

Program Management: PgMP

-

Cloud Technology: Exin Cloud Computing

-

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Conclusion

In conclusion, while the road to CTFL certification may present obstacles for candidates, with the right strategies and mindset, these challenges can be overcome. By following the tips and techniques outlined in this article, you can navigate the certification process effectively and achieve success in your CTFL exam. Remember, persistence, dedication, and a proactive approach to studying are key to overcoming obstacles and achieving your certification goals. Good luck on your CTFL journey.

Contact Us For More Information:

Visit :www.icertglobal.comEmail : info@icertglobal.com

TQM, Six Sigma, and Lean: A Comparative Analysis

href="https://www.icertglobal.com/tqm-six-sigma-and-lean-a-comparative-analysis-blog/detail" />

In the realm of quality management and process improvement, three methodologies stand out as the leading approaches to achieving excellence: Total Quality Management (TQM), Six Sigma, and Lean. Each methodology brings its own unique set of principles, tools, and techniques to the table, but they all share the common goal of driving continuous improvement and enhancing overall business performance.

Total Quality Management (TQM)

Total Quality Management, or TQM, is a holistic approach to quality management that focuses on involving all employees in the continuous improvement of processes, products, and services. TQM emphasizes the importance of customer satisfaction, employee involvement, and process improvement through problem-solving and teamwork. By implementing TQM principles, organizations can create a culture of quality that permeates every aspect of their operations.

TQM Principles

Customer Focus

Continuous Improvement

Employee Involvement

Process-Oriented Approach

Data-Driven Decision Making

Six Sigma

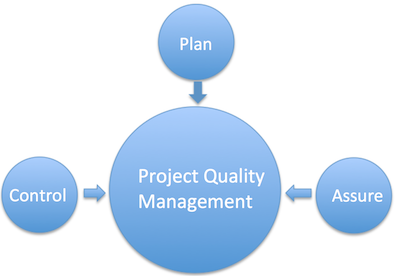

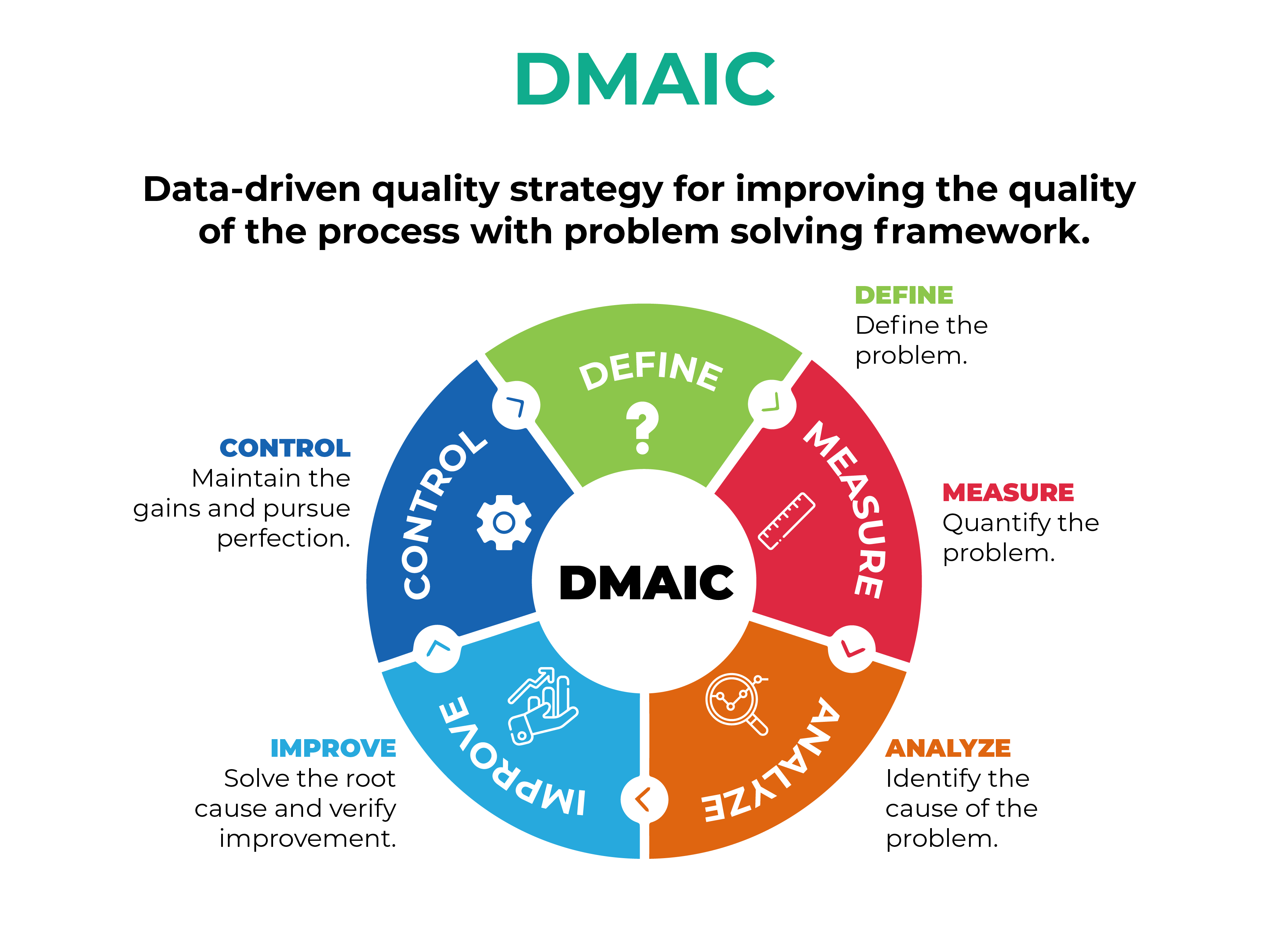

Six Sigma is a data-driven methodology that aims to reduce variation and defects in processes to achieve near-perfect quality. By employing statistical tools and analysis techniques, Six Sigma practitioners seek to identify and eliminate the root causes of problems, leading to improved process efficiency and performance. The DMAIC (Define, Measure, Analyze, Improve, Control) methodology is a fundamental part of the Six Sigma approach, guiding practitioners through the process of improving processes and delivering measurable results.

Six Sigma Tools

Control Charts

Pareto Analysis

Root Cause Analysis

Statistical Process Control

Design of Experiments

Lean

Lean, on the other hand, is focused on maximizing customer value while minimizing waste. Lean principles aim to streamline processes, reduce lead times, and eliminate non-value-added activities in order to deliver high-quality products and services efficiently. By embracing concepts such as kaizen (continuous improvement) and just-in-time production, organizations can achieve operational excellence and sustained competitive advantage through Lean methodologies.

Lean Principles

Value Stream Mapping

Pull System

Kanban

5S Methodology

Gemba Walk

TQM vs. Six Sigma vs. Lean: A Comparative Analysis

When comparing TQM, Six Sigma, and Lean, it's important to consider the strengths and weaknesses of each methodology in relation to the specific needs and goals of an organization. TQM excels in fostering a culture of quality and employee engagement, while Six Sigma is renowned for its rigorous statistical analysis and problem-solving capabilities. Lean, on the other hand, shines in its focus on waste reduction and process efficiency.

TQM vs. Six Sigma vs. Lean: Key Differences

TQM emphasizes employee involvement and continuous improvement, while Six Sigma focuses on statistical analysis and defect reduction.

Lean prioritizes waste elimination and value stream optimization, while TQM and Six Sigma have a broader quality management focus.

Six Sigma employs the DMAIC methodology for problem-solving, Lean uses tools like value stream mapping and kanban to streamline processes.

How to obtain Quality Management certification?

We are an Education Technology company providing certification training courses to accelerate careers of working professionals worldwide. We impart training through instructor-led classroom workshops, instructor-led live virtual training sessions, and self-paced e-learning courses.

We have successfully conducted training sessions in 108 countries across the globe and enabled thousands of working professionals to enhance the scope of their careers.

Our enterprise training portfolio includes in-demand and globally recognized certification training courses in Project Management, Quality Management, Business Analysis, IT Service Management, Agile and Scrum, Cyber Security, Data Science, and Emerging Technologies. Download our Enterprise Training Catalog from https://www.icertglobal.com/corporate-training-for-enterprises.php and https://www.icertglobal.com/index.php

Popular Courses include:

Project Management: PMP, CAPM ,PMI RMP

Quality Management: Six Sigma Black Belt ,Lean Six Sigma Green Belt, Lean Management, Minitab,CMMI

Business Analysis: CBAP, CCBA, ECBA

Agile Training: PMI-ACP , CSM , CSPO

Scrum Training: CSM

DevOps

Program Management: PgMP

Cloud Technology: Exin Cloud Computing

Citrix Client Adminisration: Citrix Cloud Administration

The 10 top-paying certifications to target in 2024 are:

Certified Information Systems Security Professional® (CISSP)

AWS Certified Solutions Architect

Google Certified Professional Cloud Architect

Certified In Risk And Information Systems Control (CRISC)

Certified Information Security Manager(CISM)

Project Management Professional (PMP)® Certification

Certified Ethical Hacker (CEH)

Conclusion